500ml Plastic yogurt cups machine yogurt cup filling and packing machine

This series of products are widely used in liquid filling and sealing of various plastic cups, which can automatically complete the filling, sealing, cutting, marking, ultraviolet sterilization, cup dropping sterilization and other processes, and IT can be customized according to your special requirements.

Specifications of cup water filling and sealing machine

| No. | Items | Parameter |

| Model | AF-LF | |

| 1 | Machine Speed | 2000-9000 cph |

| 2 | Filling range | 100-500ml |

| 3 | Filling Accuracy | ±1% |

| 4 | Power Source | 3P 220v50hz or customize |

| 5 | Power | 5 Kw |

| 6 | Air pressure | 0.6-0.8MPa |

| 7 | Air consumption | ≤0.5m3/min 0.4-0.6m3/min |

| 8 | Working Temperature | 5-35℃ |

| 9 | Machine Rack size | 3000*700*1700 mm |

Features of cup Yogurt filling and sealing machine

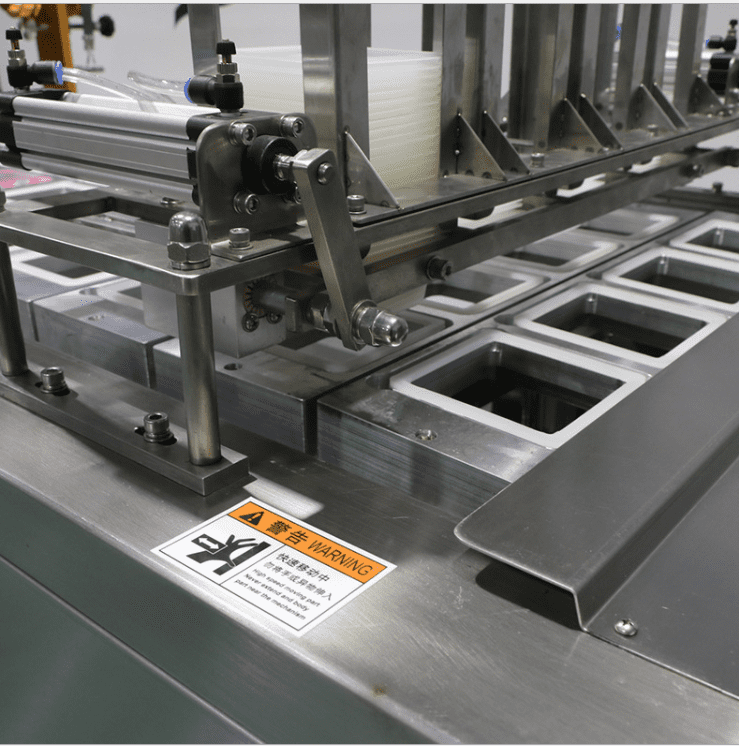

1) driven system: servo motor with planetary gear reducer for the rotary table stepping running, it can rotate very fast but avoid material splashing because servo motor can start and stop smoothly, and also keep the positioning accuracy.

2) Empty cup loading function: it adopts spiral separating and pressing technology which can avoid the cup damaging and deforming, it has vacuum sucker which can guide the cup to into the mold accuracy.

Empty cup detecting function: it adopts photoelectric sensor or optical fiber sensor to detect the mold have or haven’t empty cup, it can avoid the mistake filling and sealing if the mold without the cup, reduce the product waste and machine cleaning.

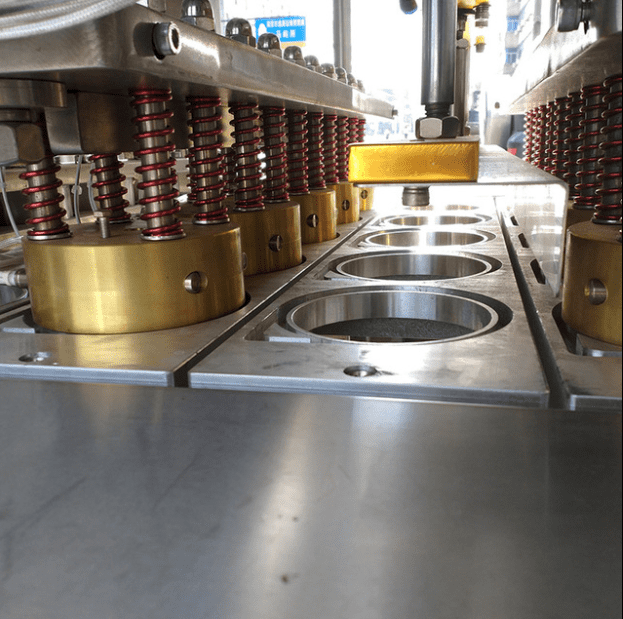

3) Quantitative filling function: it uses piston filling and cup lifting function, no splash and leakage, the filling system tool free disassemble design and also has CIP clean function.

4) Aluminum foil lids placing function: it is made up by 180 rotate vacuum sucker and lids magazine, it can place the lid on the mold fast and accuracy.

5) Sealing function: it is made up by heating seal mold and air cylinder pressing system, the sealing temperature can 0-300 degree adjustment, based on Omron PID controller and solid-state relay, temperature difference less than +/- 1 degree.

6 ) Discharge system: it is made up by cup lifting and pulling system, faster and stable.Automation control system: it is made up by PLC, Touch screen, servo system, sensor, magnetic valve, relays etc.

7) Pneumatic system: it is made up by valve, air filter, meter, pressing sensor, magnetic valve, air cylinders, silencer etc.

8) Safety guards: it is optional function, it is made up by PC plates and stainless steel, has safety switches which protect the operator.

9) Machine rack: Whole machine is made by stainless steel 304 and anodizing aluminum, ensures it can run in bad food factory environment which has damp, steam, oil, acidity and salt etc. its body can accept the water rinsing clean.