Do you want to expand Your K CUP coffee capsule production?

You need better and faster machine to meet your requirements. TRY Our AF-H2 K CUP filling sealing machine. This machine Can produce 2 capsules at a time, with around 80-100 pcs per minute.

AFPAK’S Specially designed filling system not only packs coffee powder but also produces cocoa powder, soluble powder, milk powder, and tea powder to help customers produce more diverse products to Help guests Maximize profits.

Of-course, we also have some good other filling methods to meet your needs for liquid, particle, powder, at same time, it is very easy to use, easy to clean, do not need special , maintance, it can work 24 hours continuously without any stop.

If you want to scale up production and produce more products, Choose our AF-H2 K CUP capsule filling sealing machine, YOU deserve it!

Specifications:

| No. | Items | Parameter |

| 1 | Packing speed | 80-100 c.p.min |

| 2 | Power Source | 3ph, 380V 50HZ/60HZ |

| 3 | Power | 3 Kw |

| 4 | Air pressure | 0.6-0.8MPa |

| 5 | Air consumption | 350L/min |

| 6 | Working Temperature | 5-35℃ |

| 7 | Nitrogen Consumption | 50L/min |

| 9 | Machine Rack size | L4000*W920*H2150 mm |

| 9 | Weight | 1000Kg |

High stability: Rational designed Machine can work 24 hours continuously

High accuracy: filling accuracy is stable at ±0.2g, and very stable working.

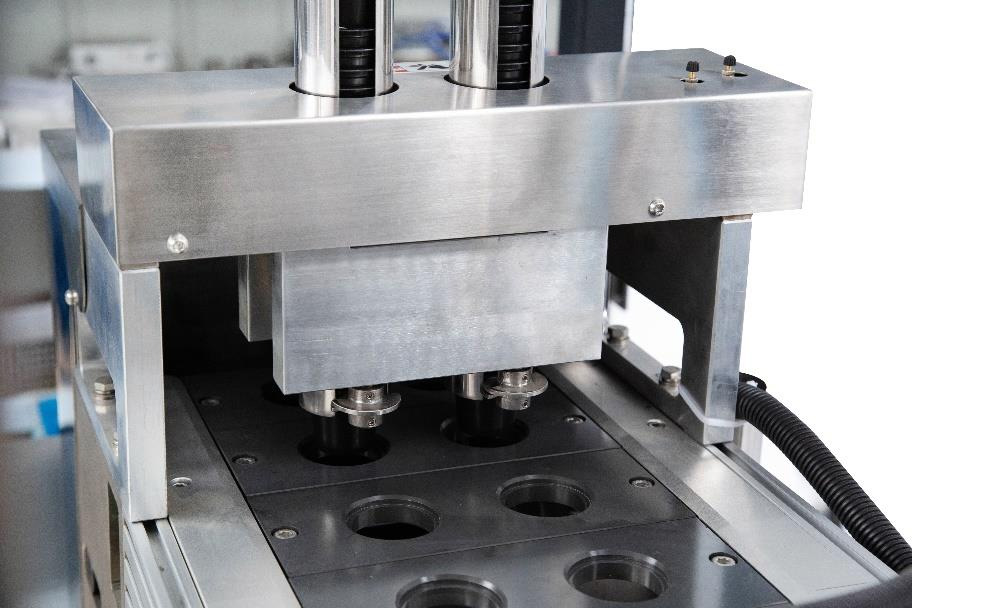

Fast speed: 2 laneS working, Produce up to 100 capsules/min

Smart working: AFPAK’s machines incorporate a variety of sensors that allows it to detect and smartly decide how to respond to the presence or absence of cups, lids, coffee, air pressure, temperature, position, etc.

Easy to Use: For extensive control of any internal parameters, the machine features an easy to use touch screen interface (HMI).

Control system: Industrial Japan PLC controller Omron/schneider. Positioning system driven by stepper motors with feedback. Touch screen (HMI) Omron/Schneider. All in English language. (If you can translate for us, we can put your language inside

Simple design,easy to operate. don’t need spend lot of time to maintain.

Small footprint layout required: you can put this machine in any places

Automatic drop empty K CUP capsule

Automatic detect whether K CUP well located on the machine by sensor.

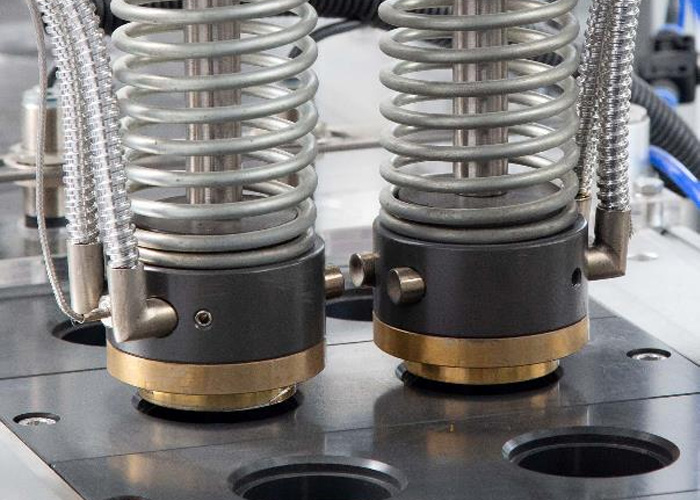

Servo motor to fill coffee while vibrating, weight around 8-12g (can be adjust) Nitrogen flushing here

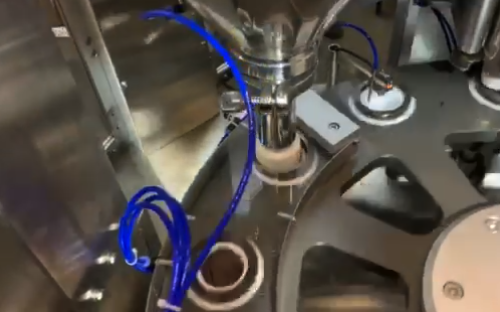

Auto suck Foil Lids (Or roll film, cutting and sealing) Nitrogen flushing here

Auto detect whether the foil lids is ready by Sensor Nitrogen flushing here

Auto Seal twice

Output to the conveyor

In-line weighing system

Cutting and putting the filter on the capsules button

Integration of pouches packaging machine

Integration of boxes packaging machine

Liquid dosing system for different favors of coffee

Auto sort capsules and feeding to the machine

Do You have the same questions?

1) Are you worried about the quality of the machine that us causing your entire production plan to fall?

2) Are you worried that complex machine maintenance is making your plant much less efficient?

3) Are you worried about the safety of your investment?

You spend a lot of time and money, and you end up with something that’s not what you thought it would be.

4) You contact to many manufacturers,do not know which is really able to provide the equipment and products you need

How about a person who can reply questions quickly and help you to solve the problems and leave you to sit back and relax?

Professional senior engineers team will design the machines as per your requirement

Well-educated workers will take care of every parts of your machines

We have over 10 patent technologies on all our machines.

We have a wealth of design and manufacturing experience, according to your requirements in-depth customization of your equipment.

There are many successful cases for you to refer to, so you do not have to worry about choosing AFPAK.